Essential Insights for Choosing an Embroidery Machine in Small Business Settings

When small business owners want to start offering embroidery services, they need to pick the right embroidery machine for their shop. Choosing poorly could mean wasted time, lower quality work, or even losing money on bad investments. There are so many options out there these days that it's easy to get overwhelmed. That's why we put together this guide with real world advice for picking a machine that fits what the business actually needs without breaking the bank. We've seen too many shops spend way too much on machines they don't really need.

Understanding Different Types of Embroidery Machines

The market offers various embroidery machine options catering to different workshop sizes and output requirements. Among them, single needle models stand out as entry level equipment for those just starting out or handling limited orders. These basic units work great for shops that need to stitch logos on caps or personalize t-shirts since they don't break the bank and operators can learn the ropes quickly. The downside? When switching between multiple thread colors during a job run, someone has to stop the machine and change threads manually every time, something that really adds up in terms of lost time on bigger projects.

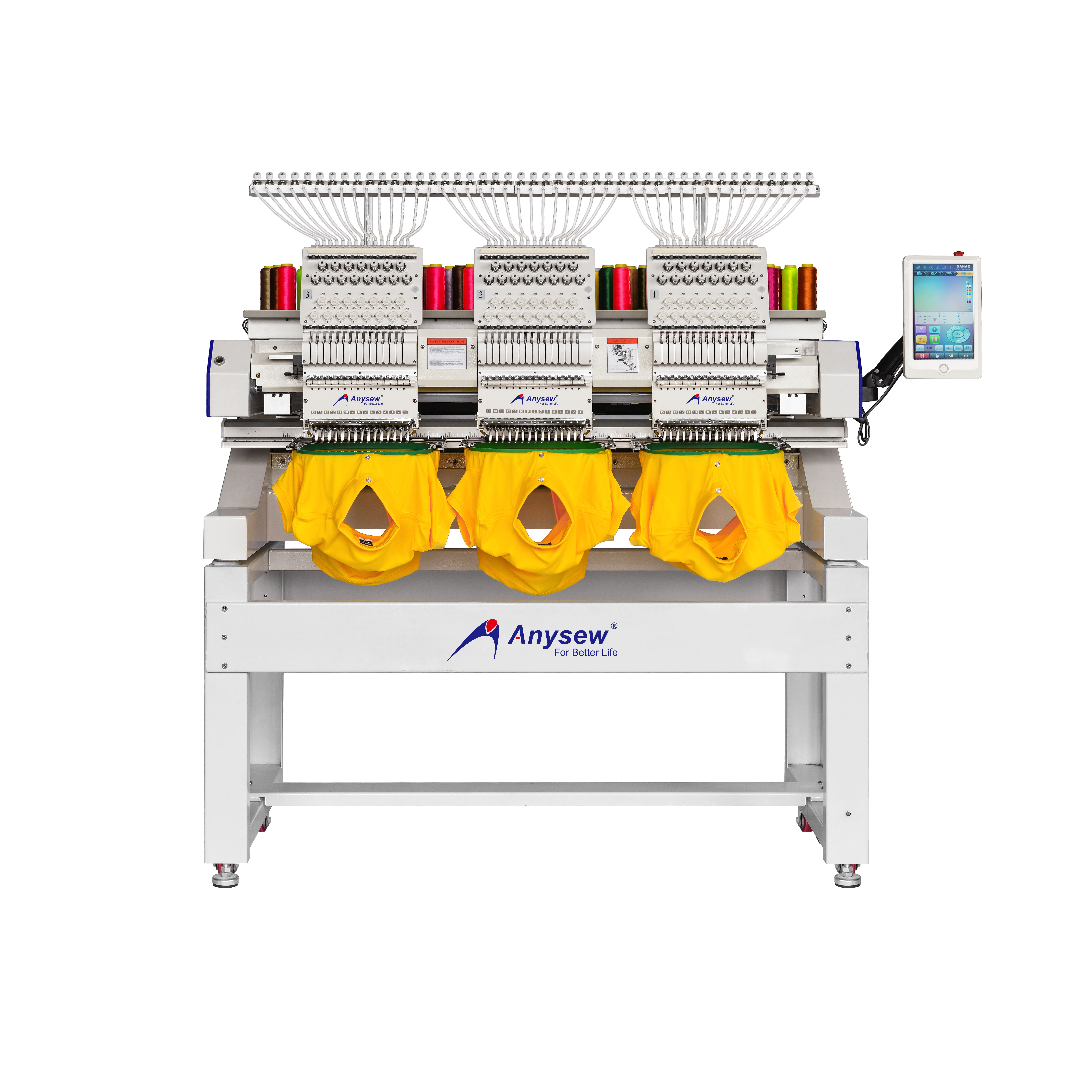

Embroidery machines with multiple needles actually carry several colored threads at once. What this means is that production speeds up considerably since the machine can switch colors automatically while running, no need to stop and change threads manually. Sure, the upfront cost is steeper compared to single needle models, but many shops find them worth it when dealing with big orders or intricate designs that require lots of color changes. These machines really shine in high volume situations where time savings translate directly into profit margins.

Stitching Speed and Production Capacity

One of the most important features to consider in an embroidery machine is stitching speed, often measured in stitches per minute (SPM). A higher SPM enables faster order fulfillment, which is essential for growing businesses aiming to meet increasing demand.

Before investing in equipment, small business owners need to take a good look at what they're currently handling plus what might come their way in the future. When the machine's speed lines up with actual production requirements, it means getting those orders done when promised while still keeping the quality intact. Companies dealing with ups and downs in customer requests find value in machines that can adjust speeds as needed. Operators can ease off the gas for intricate tasks that require attention to detail, then crank things up again when faced with big batches of standard products. This kind of adaptability makes all the difference during busy seasons or unexpected surges in demand.

Software Compatibility and Design Flexibility

Modern embroidery machines often come bundled with or support compatible design software. This software allows users to create, edit, and upload embroidery patterns directly to the machine. Software compatibility is a crucial factor because it impacts the ease of design customization and workflow efficiency.

For small businesses aiming to offer personalized or unique products, software flexibility can be a significant advantage. Intuitive software reduces the learning curve and allows even beginners to produce professional-quality embroidery. Additionally, compatibility with widely used file formats ensures that businesses can import designs created by freelancers or customers.

Budgeting and Investment Strategies for Small Businesses

Investing in an embroidery machine is a significant decision, particularly for small businesses with limited capital. It is essential to balance upfront costs with long-term value and business goals.

Evaluating Initial Costs Versus Features

Basic embroidery machines are generally more affordable but may lack features such as automatic thread trimming, multiple needles, or high-speed stitching. These features, while increasing the cost, can significantly improve productivity and reduce manual labor.

Small business owners should identify which features are necessary for their operations and which may be unnecessary luxuries. Spending more initially on a machine with better durability and automation might lead to cost savings over time through reduced maintenance and labor costs.

Financing and Leasing Options

For businesses unable to afford a high-end embroidery machine outright, leasing or financing options offer practical alternatives. Leasing enables companies to access advanced machines with lower upfront expenses and flexible payment schedules.

Some manufacturers and dealers provide financing plans tailored for small businesses, which can include maintenance packages and technical support. Such arrangements help manage cash flow while benefiting from the latest technology.

Anticipating Maintenance and Operating Costs

Maintenance costs are often overlooked but critical to budget planning. Regular servicing, replacement parts, and occasional repairs contribute to the total cost of ownership. Choosing a machine from a reputable brand with widely available parts and good customer support reduces the risk of costly downtime.

Operating costs such as thread, stabilizers, and electricity also add up. Efficient machines tend to consume fewer resources, contributing to overall savings.

Optimizing Production Workflow and Efficiency

Selecting the right embroidery machine is only the first step. To maximize profitability, small businesses must align machine capabilities with their production workflow and operational practices.

Matching Machine Capacity to Business Demand

A mismatch between machine capacity and business demand can cause delays or underutilization. For low-volume businesses focusing on customized or one-off items, single-needle machines might offer sufficient flexibility and lower operating costs.

High-volume producers benefit from multi-needle machines capable of running unattended for longer periods. Features like automatic thread trimming and thread break detection reduce operator intervention and improve throughput.

Integrating Embroidery Machine with Other Production Processes

In some small businesses, embroidery is part of a larger production line involving cutting, sewing, or packaging. Choosing an embroidery machine that integrates well with other equipment or supports automation helps streamline operations.

For example, machines with networking capabilities allow remote monitoring and program uploading, which increases operational efficiency. Businesses should consider their entire workflow when selecting an embroidery machine to ensure smooth coordination between processes.

Training and Skill Development

An advanced embroidery machineâs benefits can only be fully realized when operators are trained to use its features effectively. Investing in comprehensive training ensures staff understand machine settings, software operation, and troubleshooting techniques.

Proper training reduces production errors, machine downtime, and material waste. Many manufacturers provide training resources, including online tutorials and in-person workshops.

Maintenance Practices for Longevity and Quality

Routine maintenance is essential to keep an embroidery machine running smoothly, especially in a small business environment where reliability is critical.

Daily Cleaning and Inspection

Operators should clean lint and debris from the machine regularly, particularly around the needle area and bobbin case. A clean machine operates more reliably and produces higher-quality embroidery.

Daily inspections for worn needles, thread tension, and proper lubrication prevent many common problems. Following the manufacturerâs maintenance schedule extends machine life and reduces unexpected breakdowns.

Periodic Professional Servicing

In addition to daily upkeep, scheduling professional maintenance services helps identify and fix issues that may not be apparent during routine cleaning. Such servicing may include mechanical adjustments, software updates, and calibration.

Preventative maintenance minimizes costly repairs and helps maintain consistent embroidery quality, which is vital for customer satisfaction.

Using Quality Materials and Proper Settings

Using high-quality thread and stabilizers suited to the embroidery machine and fabric type enhances stitch quality and machine performance. Incorrect material choices can lead to thread breaks or fabric damage.

Additionally, correctly adjusting machine settings such as thread tension, stitch density, and hoop size contributes to optimal embroidery results.

FAQ

What is the difference between single-needle and multi-needle embroidery machines?

Single-needle machines have one needle and are simpler and less expensive, ideal for low-volume or custom jobs. Multi-needle machines have multiple needles loaded with different thread colors, allowing faster production and complex designs.

How important is software compatibility when choosing an embroidery machine?

Software compatibility is very important because it affects design flexibility and ease of use. Good software allows for custom pattern creation, editing, and smooth transfer of designs to the machine.

Are industrial embroidery machines practical for small businesses?

Industrial machines offer high speed and durability but often come at a high cost and complexity. Small businesses typically benefit more from mid-range or entry-level machines that fit their production scale and budget.

How frequently should an embroidery machine be maintained?

Daily cleaning and inspection are recommended, along with periodic professional servicing as per the manufacturerâs guidelines to maintain performance and prevent breakdowns.